Just How Car Plastic Parts Injection Molding Aids To Lower Manufacturing Cost?

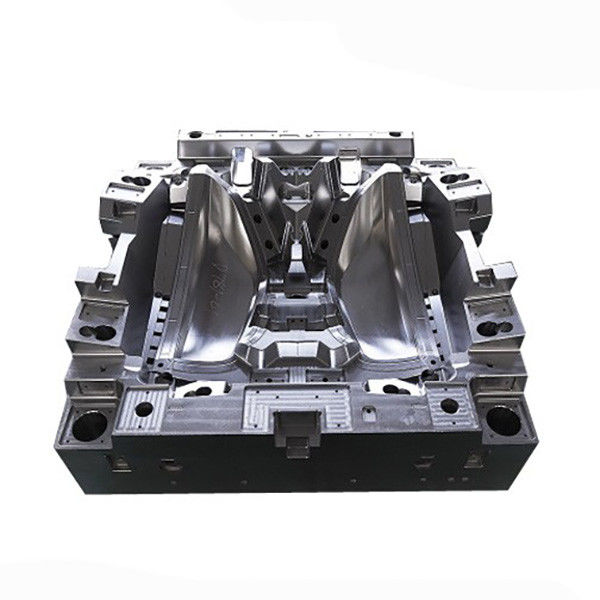

Are you searching for a method to decrease expense? Suppliers are always in search of a way to decrease their expense as well as conserve cash. There are numerous methods through which you can decrease the manufacturing price. Among the most typical and also prominent means is by using shot molding. In the car market, making plastic parts using shot molding has swiftly gained popularity. It is a manufacturing procedure that involves melting plastic pellets as well as including them to the vacant tooth cavity for molding. Injection molding is an optimal way to reduce your costs. In this write-up, we have actually gone over just how using shot molding for car components helps in minimizing cost.

Are you searching for a method to decrease expense? Suppliers are always in search of a way to decrease their expense as well as conserve cash. There are numerous methods through which you can decrease the manufacturing price. Among the most typical and also prominent means is by using shot molding. In the car market, making plastic parts using shot molding has swiftly gained popularity. It is a manufacturing procedure that involves melting plastic pellets as well as including them to the vacant tooth cavity for molding. Injection molding is an optimal way to reduce your costs. In this write-up, we have actually gone over just how using shot molding for car components helps in minimizing cost.Keep reading to understand even more about how shot molding is affordable.

Why Should You Use Injection Molding Manufacturing Method?

The Injection molding strategy is very versatile for producing automobile parts. This procedure is basic, very easy, and also effective to generate car plastic components in massive amount. The manufacturing procedure fasts that will certainly allow you to produce more parts in much less time using a single mold and mildew. This high production price makes this approach budget-friendly and also efficient.

Cars and truck plastic injection molding manufacturer - rjcmold.com - parts shot molding is the perfect method to conserve price. The entire manufacturing process of injection molding is automated. Every little thing is done by the robots and also makers that are supervised by one worker. When all the production procedure is handled by devices, it minimizes the need for numerous employees. Therefore, the manufacturer decreases their work expense by working with less employees.

Furthermore, the automated equipment aids in decreasing the production cost. This is due to the fact that the overheads are lowered that leads to a decrease in producing g expense. As less work force is utilized, you could pass the cost conserving on your customers.

The automated procedure enables you to develop exact and specific products with the help of Computer-aided layout and computer-aided production. This permits close resistance in the process of molding production.

A lot of individuals assume it is an expensive process as the price sustained for getting the tools ready is high. Nonetheless, only the first expense will certainly be expensive. Once it is covered, you could take advantage of a lower price each. When you create more automobile components, you will be able to minimize the manufacturing cost. For this reason, this is a terrific way for vehicle manufacturers to supply top quality vehicle parts while minimizing their production expense.

A Final Word

Therefore, injection molding is advanced innovation that is excellent for generating top quality ended up plastic parts of vehicles. This method is effective for creating comparable products in mass amount. RJC Mold is leading name in the mold manufacturing sector. We have actually been creating quality plastic auto parts for many years. We have comprehensive understanding concerning shot molding, making us capable adequate to assist you. We use best quality plastic for producing car components that are strong and long lasting. If you are searching for a credible car plastic part injection molding firm, we are the right choice. So, call us today to learn more.

Created at 2019-07-16

Back to posts

This post has no comments - be the first one!

UNDER MAINTENANCE